Historically, Sakai, Osaka, was a hotbed for katana (Japanese sword) blacksmiths, and it still holds a prominent place among Japanese cutlery producers, particularly professional chefs. Our article focuses on Yamawaki Cutlery’s knives, a maker that continues to develop knives in Sakai.

Nestled in the heart of Sakai, Osaka, Yamawaki Knives stands as a testament to Japan’s rich tradition of blade craftsmanship. As we embark on a journey to explore the legacy of this revered brand, we peel back the layers of history, technique, and artistry that define the soul of Yamawaki knives.

Contents

- History of Sakai Blades

- Yamawaki Knives Unveiled

- Craftsmanship, Techniques, and Products

- OMAKASE Product Recommendations

- Maintenance

- In Conclusion

1. History of Sakai Blades

The origins of blade production in Sakai date back centuries, making it a vital hub in Japanese history for crafting exceptional blades. Sakai blades have been revered by samurais and chefs alike, and they have earned a global reputation for unparalleled craftsmanship. This region has been instrumental in shaping Japan’s proud legacy of blade-making expertize.

The story of Sakai’s blade craftsmanship is deeply entwined with Japan’s historical fabric. With roots dating back to the days of samurais, Sakai evolved into a paramount center for sword production during the Kamakura period (1185–1333). Renowned for its iron-rich soil, the region became a forging ground for master swordsmiths, contributing to Japan’s martial prowess.

As the Edo period (1603–1868) unfolded, Sakai’s reputation for crafting exceptional blades extended beyond the battlefield. The region’s expert swordsmiths transitioned their skills to meet the demands of a burgeoning merchant class. Sakai blades have become a symbol of status and craftsmanship, used not only for war but also in daily life.

Fast forward to the present, and Sakai remains a cradle of knife craftsmanship. The same precision and dedication that once went into forging samurai swords is now channeled into creating exquisite kitchen knives. Sakai blades are celebrated not only in Japan but also globally, with a reputation for unparalleled sharpness and quality.

2. Yamawaki Knives Unveiled

Since its founding in 1927, Yamawaki Cutlery has specialized in creating high-quality knives. The company sells knives for various purposes, including household use and cooking schools. An interesting fact is that one of the popular brands of knives manufactured by the company is named after Go Umanosuke Yoshihiro, one of the Three Legendary Swordsmiths of Japan from the Kamakura period (1185 - 1333) and one of Japan’s most famous swordsmiths.

The recent boom in Japanese knives was partly sparked by Yamawaki Cutlery, whose knives have won acclaim abroad. Although Yamawaki Cutlery initially only focused on producing knife handles, they quickly established an internal division for sharpening blades, setting the standard for high-end Japanese honyaki blades, or knives made entirely of steel.

Established by master craftsman Heijiro Yamawaki, the brand swiftly gained acclaim for its commitment to precision and innovation. Carrying the torch of Sakai’s legacy, Yamawaki seamlessly blends traditional techniques with modern craftsmanship, ensuring that each blade is a work of art.

Owing to its dual specialization in knife sharpening and handle attachment, Yamawaki Cutlery is an exceptional Sakai knife manufacturer.

Yamawaki’s in-house blade sharpening workshop produces exquisite Japanese knives with uncompromised sharpness and beauty, which is the pride of their craftsmen. Over a long period, the company has supported numerous knife specialty shops, assisting dealers in honing their ability to recognize genuine quality and authentic knives.

Additionally, the business makes a big effort to train its artisans so that the notoriously challenging "mizuyaki honyaki" blade forging method, which is a traditional water-quenching forging technique used to create professional-grade, high-quality cooking knives, can be used more frequently.

3. Craftsmanship, Techniques, and Products

It is thought that the production of Sakai knives began in the 15th century when a group of knife blacksmiths descended from swordsmiths and moved to Sakai from Kaga Province (now known as Ishikawa Prefecture).

Knives can be divided into two categories: those that are mechanically pressed from a mold (also known as "uchi hamono") and those that are hammered by hand. The original method, known as "tanzo" (forging) in Japanese, involves heating softened iron or steel until it glows red before hammering and shaping the metal with tools such as a hammer. The metal’s molecules cluster when it is pounded, giving it more strength and density while also making it more malleable. The final result is a stunning piece of art with exceptional sharpness and durability.

Knives forged by hand using the "uchi hamono" technique are works of art fashioned from fire, iron, and water. Forging, sharpening, and attaching the knife handle are the three main stages of production. Every step of the production process is completed by an expert as each of these tasks is typically performed by a different craftsman. Each craftsman can refine their particular skill to the fullest extent, resulting in an extreme level of quality that is unmatched elsewhere.

Yamawaki’s range of techniques and blades is a masterclass in versatility. From the artful precision of hand-forging to the cutting-edge technology employed, each blade is a fusion of tradition and innovation. Their extensive product line includes chef knives, utility knives, and specialty blades, each carefully crafted to elevate culinary experiences. The Damascus series, renowned for its intricate patterns, stands as a testament to their mastery.

4. OMAKASE Product Recommendations

Yamawaki Cutlery does not solely focus on quality; they place equal emphasis on the knife’s other features, such as the wooden handle, in addition to its sharpness and aesthetic appeal. Knives are essential everyday tools used when preparing all types of cuisine, including Japanese cuisine. As such, the company hopes to be able to share its products with the world with its catchphrase, "Knife is Life."

1.Yamawaki Blue Steel No.2 Santoku Knife

The Yamawaki Blue Steel No.2 Santoku Knife—an all-purpose master crafted for precision in slicing, dicing, and mincing. Renowned for unparalleled sharpness and remarkable durability, this knife is a testament to Japanese craftsmanship.

The distinctive octagonal handle, meticulously carved from Japanese oak with a captivating blue gradation, not only ensures ergonomic comfort but also adds a touch of unique beauty to this essential kitchen tool.

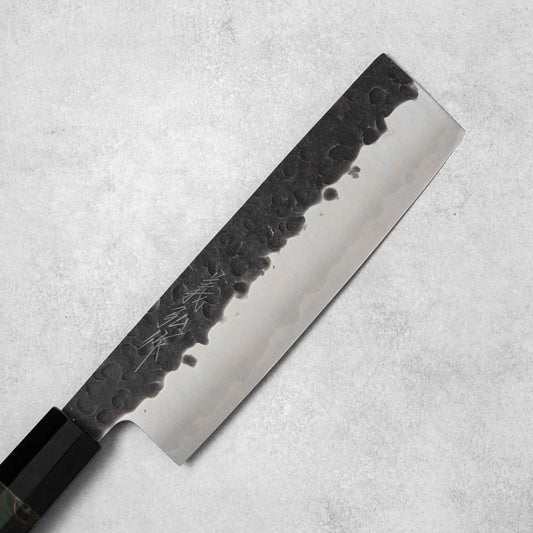

2.Yamawaki MO-V Kuro Tsuchime Nakiri Knife

The Yamawaki MO-V Kuro Tsuchime Nakiri Knife is embraced for its culinary versatility. This knive, crafted from Molybdenum Vanadium stainless steel, seamlessly navigate through an array of kitchen tasks. Whether it's the finesse of delicate slicing or the strength of robust chopping, these blades showcase their prowess.

This Nakiri Knife has been specifically designed to cut vegetables, whether a soft tomato or a hard pumpkin. With a stain-resistant material, they're not just tools but trusted companions, catering to the needs of both seasoned chefs and home cooks alike.

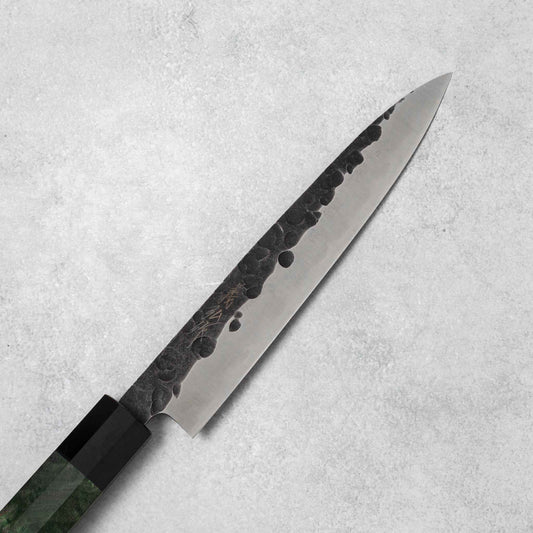

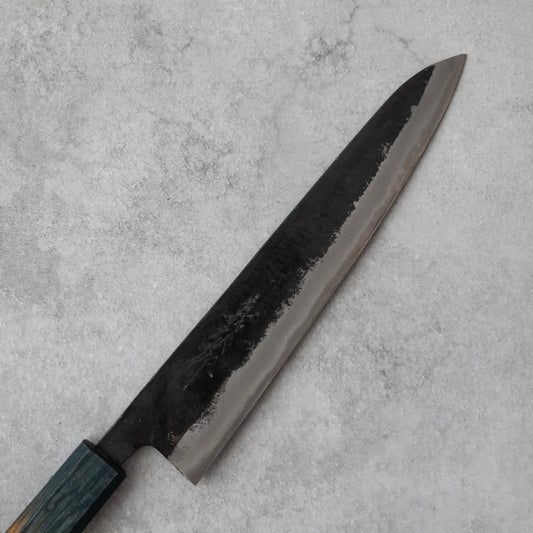

3.Yamawaki White Steel No.2 Kasumi Yanagiba Knives (Right-handed)

The Yamawaki White Steel No.2 Kasumi Yanagiba Knives (Right-handed) designed for right-hand use, is a precision-crafted culinary tool tailored to the demands of traditional Japanese cuisine. Its single bevel, long and slender design is honed for slicing through delicate items like sashimi with finesse, facilitated by an asymmetrical grind for sharp and precise cuts.

Crafted from high-quality steel, these knives often boast a hardwood handle for a comfortable grip and precise control during intricate cutting tasks. The right-hand orientation aligns with traditional Japanese techniques, making it an essential choice for chefs and sushi enthusiasts seeking authenticity and excellence in their culinary pursuits.

5. Maintenance

Maintaining a Japanese knife does not have to be as difficult as owning a traditional sharpening tool, but there are some key things to remember:

- To maintain the sharpness and longevity of your Japanese knife, it's crucial to hand wash it immediately after use with a mild detergent and warm water.

- Avoid abrasive materials and the dishwasher, as they can damage the blade and handle.

- Additionally, ensure thorough drying to prevent corrosion.

- Periodically sharpen the knife using a whetstone to retain its edge.

Store your Japanese knife properly by using a knife block, magnetic strip, or blade guard to protect the edge and prevent accidents. Avoid storing it in a drawer with other utensils to prevent nicks and scratches. Regular maintenance and proper storage will keep your Japanese knife in optimal condition for precision cutting.

For more detailed information, we have our blog on 6 top tips to care for your Japanese knife. A must read for keeping your tools sharp!

In Conclusion

In the tapestry of Sakai's illustrious blade-making history, Yamawaki Knives emerges as a luminary, seamlessly blending the time-honored craftsmanship of the samurai era with the contemporary demands of culinary excellence. Forged in the crucible of tradition, each Yamawaki blade narrates a saga of resilience, evolution, and unwavering commitment to quality.

As Sakai's legacy lives on through the keen edges of these knives, Yamawaki stands as a testament to the enduring spirit of Japanese blade artistry, inviting enthusiasts to embark on a culinary journey where history and innovation converge in every precise cut. With Yamawaki Knives, the past's artistry becomes the present's culinary masterpiece.